Case Study: Power Quality Stabilization for Renewable Natural Gas Facilities

Segment and Application

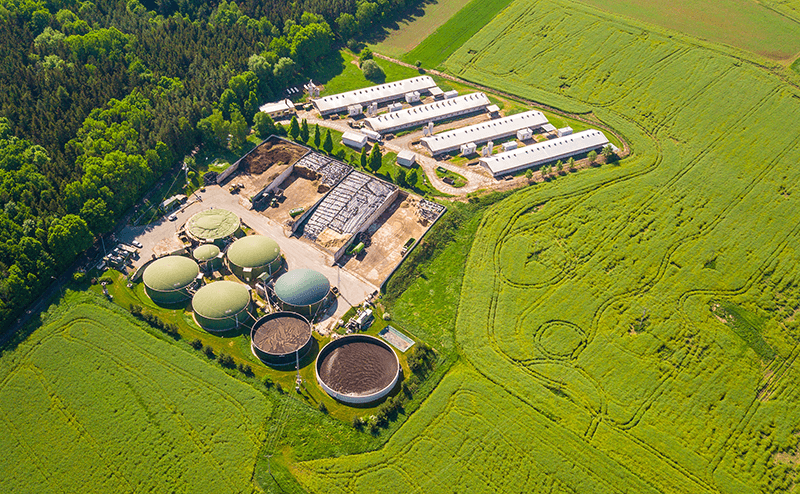

A leading renewable energy developer is building a network of landfill-based renewable natural gas (RNG) facilities. Each site captures biogas produced by decomposing waste and upgrades it into pipeline quality gas. The upgrading process depends on continuous operation of blowers, compressors, chillers, and purification skids. These systems require stable electrical conditions to maintain gas quality, manage pressure, and keep production running without interruption.

The Design Challenge

During a recent project, the customer approached HPS with concerns about electrical instability at one of their landfill RNG facilities. They reported inconsistent compressor performance, nuisance drive trips, and voltage fluctuations during load changes. These issues are common in environments dominated by non-linear equipment.

A power quality assessment was conducted to evaluate both the 480V process bus and the upstream 12.47 kV system. The findings confirmed significant harmonic distortion that directly affected equipment operation and overall site stability.

Key challenges identified:

- Approximately 99% non-linear load on the main 480V transformer

- Extensive use of six pulse variable speed drives creating harmonic distortion

- Voltage distortion above IEEE-519 limits on the primary bus

- Harmonic currents spreading into upstream equipment and distribution components

- Analysis showing more than 600A of corrective filtering required for compliance

Distorted waveforms created by non-linear loads directly affect equipment reliability, thermal performance, and long-term service life. The customer needed a repeatable design that would stabilize their electrical system across all current and future RNG facilities.

About IEEE-519

IEEE-519 is the primary industry standard that limits harmonic distortion on electrical systems. Most facilities must keep total harmonic distortion near 5% to protect equipment, maintain stable voltage, and meet utility connection requirements. This guidance is especially important for facilities with continuous non-linear loads.

The HPS Solution

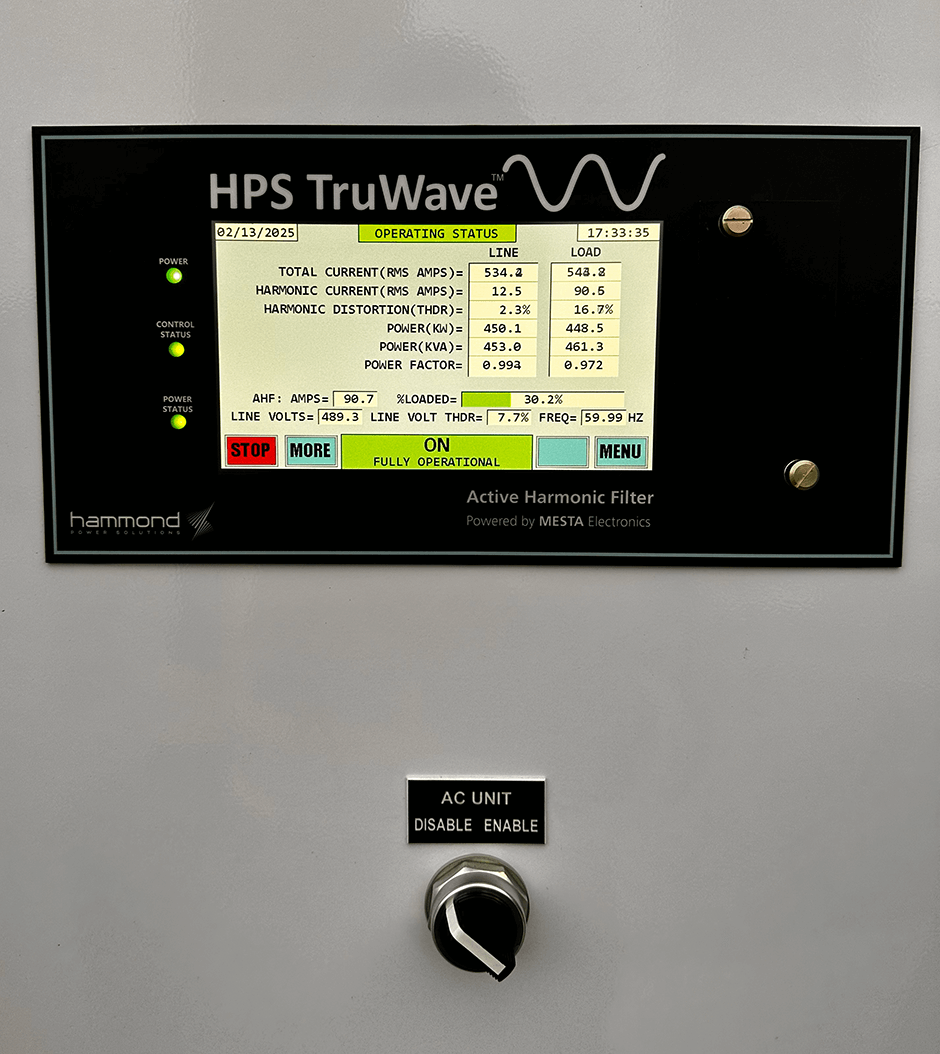

HPS supplied the HPS TruWave™ Active Harmonic Filter as part of a standardized electrical architecture developed for this customer’s landfill gas facilities. The system was installed at the primary non-linear bus, directly targeting the point of harmonic generation. The solution was engineered for repeatable deployment across all future sites and commissioning support was coordinated through internal field services and installation partners. The HPS TruWave continuously measures system conditions and injects corrective current that cancels harmonic content at its source.

Results

Commissioning feedback confirmed clear improvements in both power quality and plant performance.

Observed results:

- Significant reduction in harmonic current on the 480V bus

- Lower voltage distortion with improved overall system stability

- Steadier compressor operation with fewer nuisance trips

- More consistent purification and control system performance

- Reduced electrical stress on major distribution equipment

Customer outcome:

The improvement demonstrated immediate and repeatable value, leading the developer to standardize this electrical design and the HPS TruWave system across their entire RNG portfolio. The approach provides a reliable path to IEEE-519 compliance and long-term equipment protection for any facility with concentrated non-linear loads.

More from the HPS Blog

Microgrids & Power Quality: Designing Resilient, Clean Facility Power - Article

A microgrid is more than just backup, when designed properly, it becomes a platform for resiliency, efficiency, and sustainability. One of the most critical and underappreciated design challenges in microgrids is power quality.