Case Study: Cast-Resin Transformers for High-Profile Manhattan Financial Firm

Challenge

A leading global financial firm in Manhattan was expanding its infrastructure and required the installation of additional electrical service within their headquarters. Although the building was not yet occupied, the need for these transformers arose late in the construction process, after much of the electrical work had already been completed. As a result, access was limited, creating a major logistical challenge for bringing in large electrical equipment.

The project required a power solution that was reliable, fire-safe, and low-maintenance, while also maintaining uptime for the critical infrastructure in this building.

Solution

Working in conjunction with our New York City Manufacturer Representative, SDM METRO, Hammond Power Solutions (HPS) provided eight high-reliability cast-resin transformers, customized to meet the project's specifications. Space limitations caused by the advanced stage of construction meant that several design iterations were completed during the approval process to reduce the overall size of the units and accommodate the restricted footprint available for the switchgear line-ups.

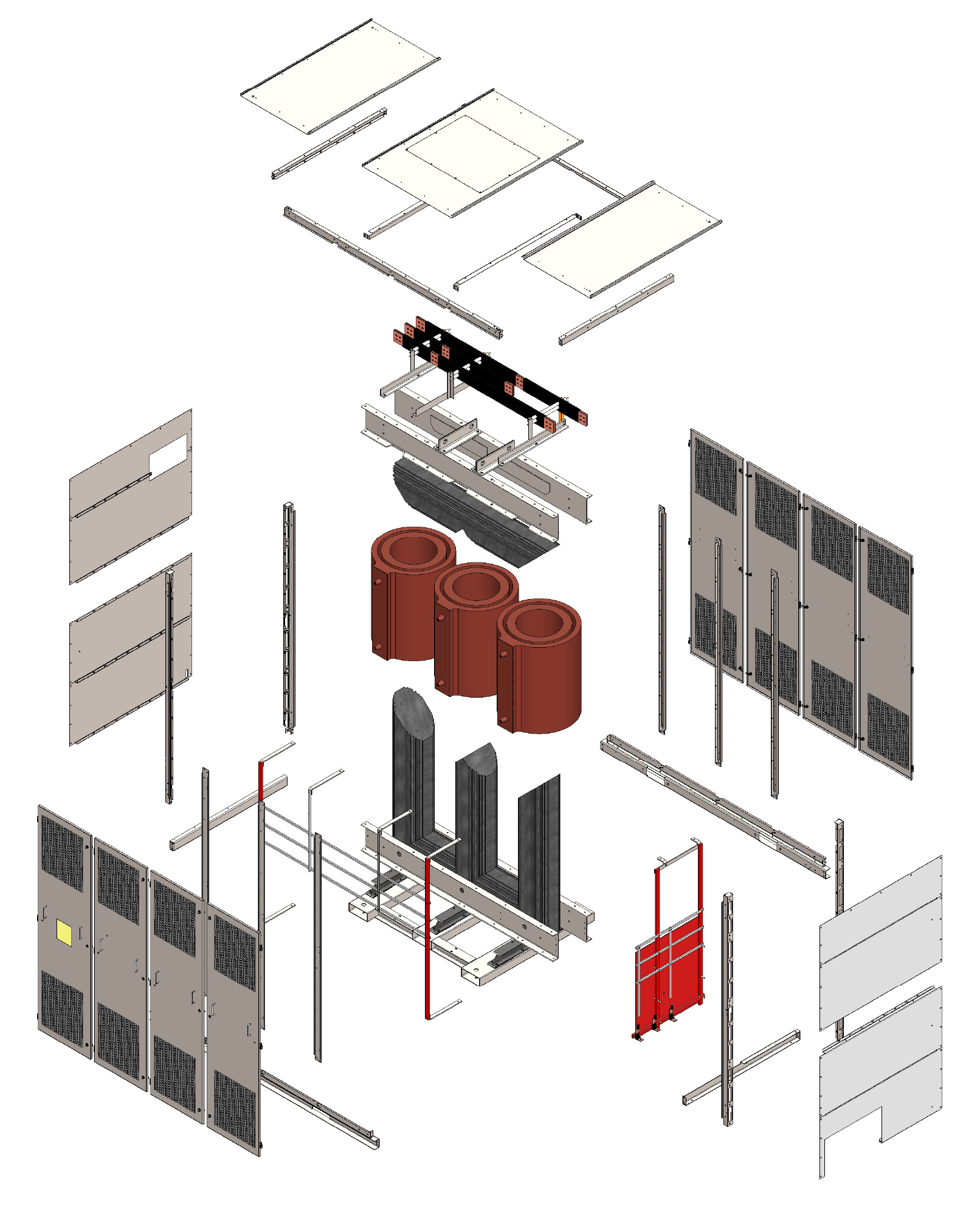

Additionally, because of the building’s constraints, the transformers were fully disassembled down to their cores and transported piece-by-piece up through the elevator shaft. This approach is known as an HPS triplex solution, a configuration in which three single-phase transformers are connected and housed together as a single three-phase unit. Triplex transformers can be broken down into lighter, more manageable components for easier transport in size- or weight-restricted environments such as elevator shafts or confined mechanical rooms.

Cast-resin dry-type transformers are particularly well-suited for critical infrastructure projects like this one, offering high reliability, minimal maintenance requirements, and enhanced fire resistance compared to traditional oil-filled designs. Their robust insulation system and sealed windings protect against the ingress of moisture, dust, and environmental contaminants, making them ideal for installations within occupied commercial spaces where safety, reliability, and low maintenance are essential.

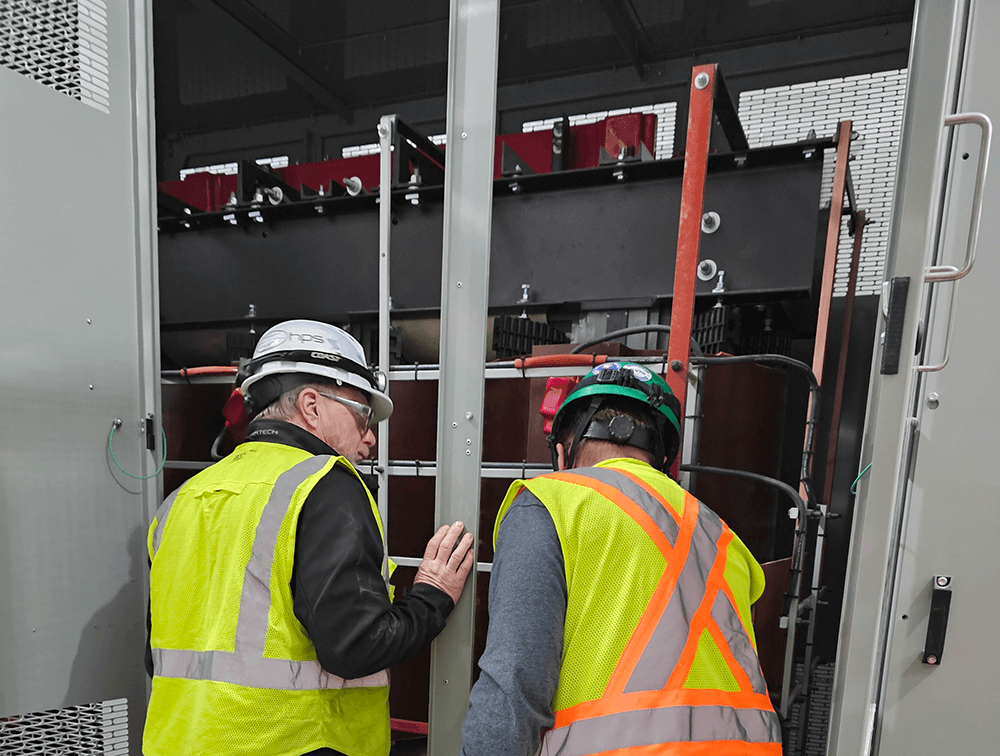

Once onsite, HPS Field Services meticulously reassembled each unit to ensure full functionality and compliance with the project’s stringent quality standards.

Execution

Project Timeline: Approximately one year from initial quote to product delivery.

Installation: HPS Field Services dedicated approximately 30 days (on and off site) to complete the complex reassembly onsite.

Collaboration: This project required close coordination between the HPS engineering, field service, and project management teams, working in partnership with the customer to ensure a smooth and successful installation despite the logistical hurdles.

Results

The project was completed successfully, with strong positive feedback from the project stakeholders regarding the performance of HPS’s transformers and the professionalism shown throughout the installation process.

Reliable cast-resin transformers now support the firm’s critical infrastructure, helping to ensure uninterrupted operations at one of Manhattan’s most prominent addresses.

More from the HPS Blog

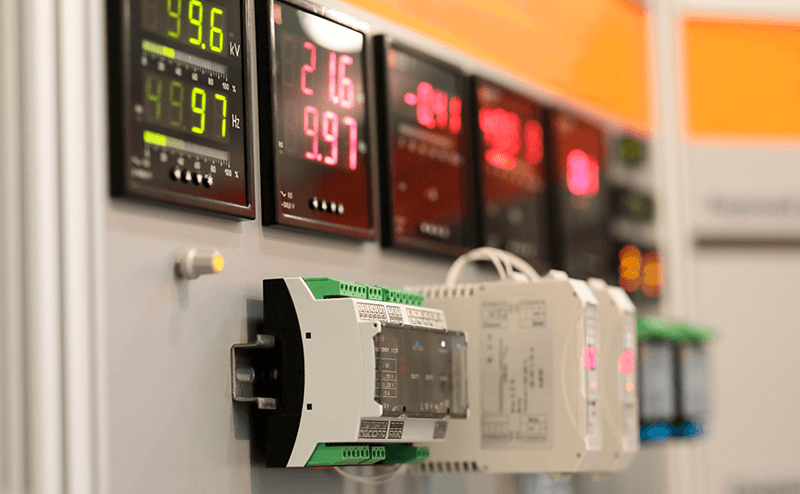

Understanding the Growing Demand for Onsite Power Quality Metering - Podcast

As power systems become more complex and industries rely increasingly on sensitive electronic equipment, onsite power quality metering is becoming an essential tool for facility operators.