Understanding the Growing Demand for Onsite Power Quality Metering

As power systems become more complex and industries rely increasingly on sensitive electronic equipment, onsite power quality metering is becoming an essential tool for facility operators. In a recent discussion featuring Dan Davis from Hammond Power Solutions and Ali Halimi from SMAART Power, key insights were shared about the importance of power quality monitoring and how businesses can address emerging challenges.

Listen to the full conversation here.

Key Takeaways

Why Power Quality Matters

Power quality has evolved into a critical issue due to the rise in automation, renewable energy integration, and modern electronic loads. Facilities today are more susceptible to power disturbances such as harmonics, voltage sags, and transients, which can lead to equipment malfunctions, inefficiencies, and costly downtime. As companies modernize, many struggle with a patchwork of old and new equipment that may not be optimized for consistent power quality.

The Role of Onsite Power Quality Metering

Onsite power quality metering provides real-time insights into a facility’s electrical performance. By deploying specialized meters, engineers can assess factors such as harmonic distortion, voltage fluctuations, and grounding issues. The data collected allows for proactive maintenance, reducing the risk of unexpected failures and improving overall efficiency. Industries such as manufacturing, data centers, healthcare, and water treatment facilities have seen a rise in power quality challenges. Sensitive equipment like CNC machines, robotics, and medical devices require stable power to function reliably. Even minor fluctuations can cause operational disruptions and financial losses.

When Should Facilities Consider Power Quality Metering?

Common signs that indicate a need for onsite metering include:

- Unexplained equipment shutdowns or malfunctions

- Flickering lights or voltage instability

- Frequent circuit breaker trips

- Increased energy bills due to inefficiencies

- Audible transformer or motor noise

By diagnosing these issues early, businesses can implement targeted solutions such as harmonic filters, upgraded transformers, or system-wide power management strategies.

Solutions from HPS and SMAART Power

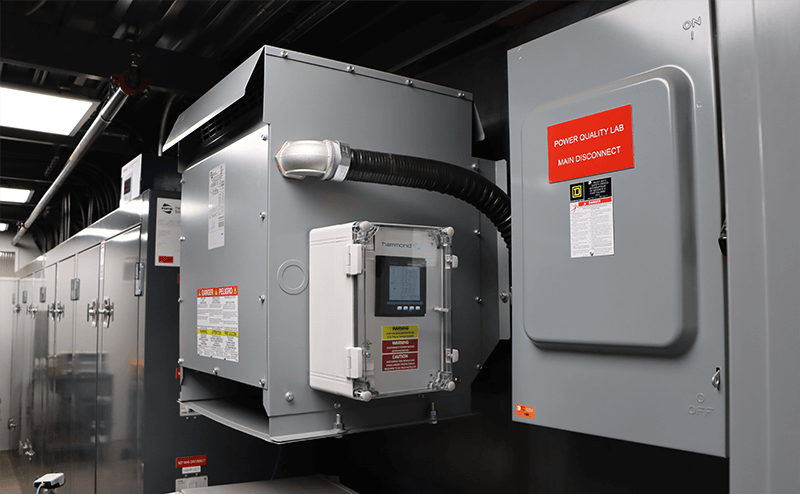

Hammond Power Solutions (HPS) and SMAART Power offer comprehensive solutions to address power quality concerns. HPS provides a broad range of power quality products, including harmonic mitigating transformers, line reactors, and filters designed to minimize electrical disturbances. SMAART Power specializes in onsite analysis, long-term monitoring, and customized corrective measures, ensuring facilities can optimize their electrical infrastructure.

Next Steps for Facility Operators

For businesses looking to improve power quality, the first step is a consultation to assess current electrical conditions. Onsite power quality surveys typically involve data collection over one to four weeks, followed by detailed analysis and tailored recommendations. Depending on the complexity, full assessments can take up to ten weeks, leading to actionable solutions that enhance efficiency and reliability. As power systems continue to evolve, investing in power quality metering ensures long-term operational success. For facility managers and engineers, understanding and managing power quality is no longer optional—it’s essential for maintaining a stable, cost-effective, and future-ready electrical system.

For more insights, listen to the full podcast discussion available on this page.

More from the HPS Blog

Optimizing Power Management with Smart Transformers - Article

As power systems become more complex and industries rely increasingly on sensitive electronic equipment, onsite power quality metering is becoming an essential tool for facility operators.