Optimizing Power Management with Smart Transformers

Addressing the Aging Transformer Infrastructure in the U.S.

In the U.S., the electrical grid’s transformer infrastructure is increasingly becoming a critical concern. Many of the transformers in use today are well beyond their expected operational lifespan. The average age of a working transformer is approximately 38 years, with more than 70% of transformers being over 25 years old. This aging infrastructure is becoming more prone to inefficiencies and failures, which jeopardize the reliability of power systems across the country.

The risks of equipment failure are compounded by the sometimes-hidden nature of transformers. Many are poorly documented, located in hard-to-access places, or simply forgotten until something goes wrong. In critical industries, such as healthcare, manufacturing, and data management, transformer failures can have catastrophic consequences. The ability to anticipate and address these risks proactively is becoming more urgent than ever.

The Role of IIoT-Enabled Smart Transformers in Power Management

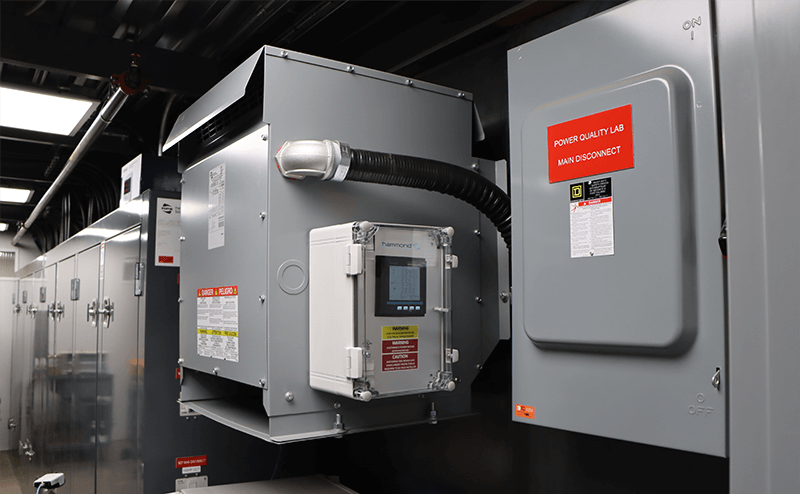

The solution to the challenges posed by aging transformers lies in proactive management, made possible by Industrial Internet of Things (IIoT)-enabled smart transformers. These devices integrate real-time monitoring, analytics, and advanced communication capabilities to improve the way transformers are managed and maintained.

The solution to the challenges posed by aging transformers lies in proactive management, made possible by Industrial Internet of Things (IIoT)-enabled smart transformers. These devices integrate real-time monitoring, analytics, and advanced communication capabilities to improve the way transformers are managed and maintained.

The integration of IIoT in transformers allows for continuous monitoring, enabling predictive maintenance that addresses potential issues before they become critical. By collecting and analyzing real-time data, smart transformers offer valuable insights into their health, helping operators make more informed decisions about when and how to maintain their equipment.

Predictive Maintenance: The Shift from Reactive to Proactive

Traditionally, transformer maintenance has been a reactive process—transformers are inspected periodically, and maintenance is performed only when problems arise. However, with aging infrastructure, this method becomes increasingly inefficient and risky. Environmental stressors like moisture, temperature fluctuations, and overloading cause gradual damage to transformers, often going unnoticed until a failure occurs.

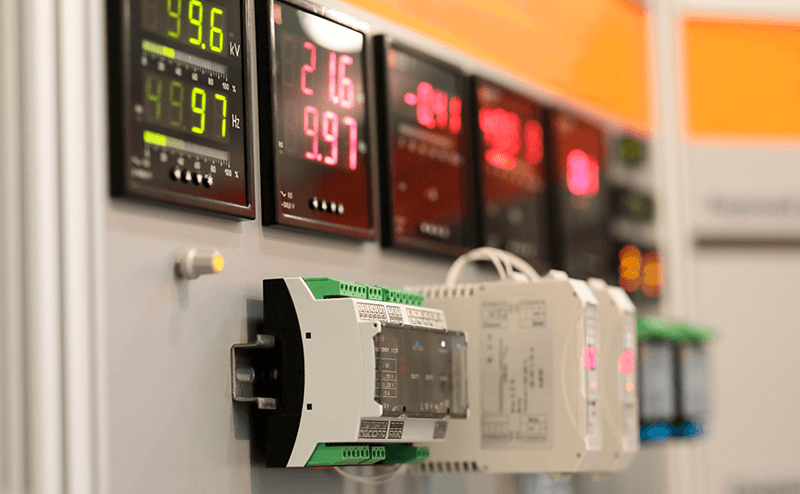

IIoT-enabled smart transformers, on the other hand, offer continuous monitoring of key parameters such as power quality issues, demand profile, voltage fluctuations, load and phase imbalances, and a digital record of the transformer for asset management. By tracking these factors in real-time, operators are alerted to potential issues before they escalate, enabling them to perform maintenance at the most convenient and cost-effective times.

Predictive maintenance not only helps to avoid unplanned downtime but also allows for better resource allocation and more efficient use of maintenance personnel and budgets. This shift to a proactive model minimizes disruptions and ensures that transformers operate at optimal performance for longer.

One of the standout features of these devices is their time-stamped data logging capability. This means that every piece of data recorded is accurately time-stamped, providing a precise historical record of system performance and events. This is crucial for troubleshooting and performance analysis.

Optimizing Energy Usage and Reducing Costs

Beyond preventing transformer failures, smart transformers play a crucial role in optimizing energy usage. With real-time data analysis, operators can gain insights into energy consumption patterns, power quality issues, and inefficiencies in the system. This data can then be used to adjust operations for maximum efficiency, potentially leading to significant cost savings.

Smart transformers also enable better energy demand management. By understanding when and how energy is being used, operators can adjust their operations to align with off-peak electricity rates, reducing costs and improving the facility's overall energy efficiency. This is particularly valuable in regions with varying electricity rates, where energy consumption patterns can be optimized to take advantage of lower-cost power during off-peak hours.

Integration with Existing Systems

One of the standout features of IIoT-enabled smart transformers is their ability to integrate seamlessly into existing automation systems. These devices support a wide variety of communication protocols, such as Modbus, TCP/IP, and Ethernet IP, making them highly adaptable to different industries and applications. This flexibility ensures that businesses do not have to overhaul their entire infrastructure to take advantage of the benefits of smart transformers.

By integrating with existing systems, smart transformers provide a unified view of power management across a range of devices. This interconnectedness enables businesses to gain a more comprehensive understanding of their energy systems, helping them to optimize performance, reduce costs, and improve operational efficiency.

Real-Time Alerts and Custom Dashboards

Smart transformers are equipped with real-time alert systems that notify operators when key parameters exceed predefined thresholds. Whether it’s a spike in demand, voltage, or a sudden change in power factor, these alerts help operators quickly identify potential issues and take corrective action before they lead to failures.

Moreover, these devices come with customizable dashboards, allowing users to prioritize the metrics that matter most to their specific operations. Whether you're managing a manufacturing plant, a commercial building, or a renewable energy facility, the ability to tailor the dashboard ensures that the right data is always at your fingertips. This customization makes it easier for operators to track the health of their transformers and make decisions based on the most relevant data.

Remote Monitoring for Enhanced Flexibility

Another key benefit of IIoT-enabled smart transformers is remote monitoring. With the ability to access performance data from anywhere, operators can monitor the health of their transformers and power systems without needing to be physically present. This is especially valuable in facilities that are spread across large geographical areas or in situations where operators are working off-site.

Remote monitoring also allows for quicker responses to potential issues. When a problem is detected, operators can log into the system, review the data, and take necessary action without the delays associated with on-site inspections. This enhanced flexibility and responsiveness can lead to improved system uptime and performance.

Ensuring Cybersecurity and Data Integrity

As the energy sector becomes more connected, cybersecurity becomes an increasingly important consideration. IIoT-enabled smart transformers are designed with robust encryption protocols, such as HTTPS, to ensure that all data transmitted is secure and protected from unauthorized access. This encryption ensures that sensitive performance data remains confidential, safeguarding both operational integrity and user privacy.

Given the growing number of connected devices within the grid, securing data transmission is paramount. With smart transformers, businesses can focus on optimizing performance rather than managing security risks.

The Path Toward a Smarter, More Sustainable Power Grid

The shift to IIoT-enabled smart transformers is a necessary step in building a smarter, more sustainable power grid. As energy demands continue to rise and the need for reliable, efficient power systems becomes more urgent, these advanced devices offer a way to address the challenges of aging infrastructure while enabling greater operational efficiency.

By leveraging the power of real-time data, predictive maintenance, and energy optimization, smart transformers help ensure that power systems are not only more reliable but also more adaptable to the growing demands of modern industries. With their ability to integrate seamlessly into existing systems, offer remote monitoring capabilities, and provide valuable insights into energy use, smart transformers represent the future of power management.

In an era where every second counts, proactive power management made possible by smart transformers is essential for preventing costly failures, optimizing energy consumption, and building a resilient electrical grid that can support the needs of tomorrow.

More from the HPS Blog

Understanding the Growing Demand for Onsite Power Quality Metering - Podcast

As power systems become more complex and industries rely increasingly on sensitive electronic equipment, onsite power quality metering is becoming an essential tool for facility operators.