Designing for Demand: The Role of Transformers in a Resilient EV Future

Transformers in the EV Charging Boom: Are We Ready for the Load?

As electric vehicles (EVs) continue their rapid rise, one question looms over the energy sector, municipalities, and developers alike: Is our infrastructure truly ready for the surge in demand?

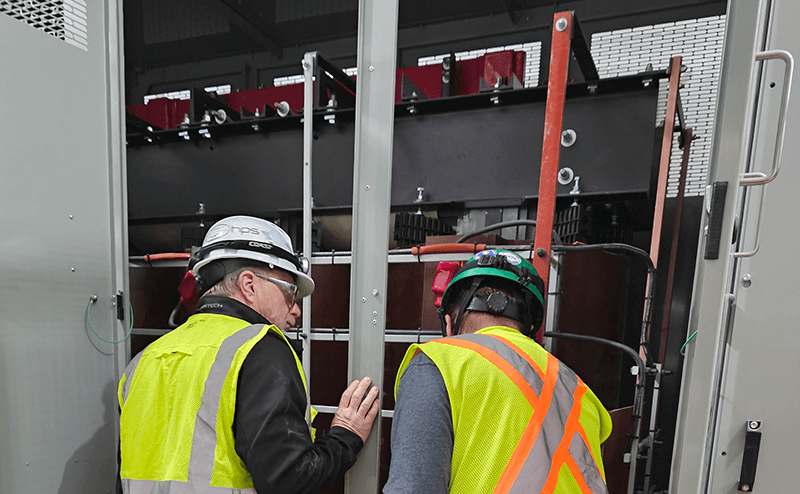

From city streets to highway rest stops, new EV chargers are popping up across North America. But while charging stations get all the attention, there’s a critical component working behind the scenes, often overlooked, but absolutely essential: the transformer.

Behind Every Charger is a Transformer

At the heart of every functional charging station is a transformer converting high-voltage electricity from the grid into usable power for EVs. But as installations grow in size and complexity, not just any transformer will do.

If EV charging transformers can’t meet the demands of this application, the consequences can include:

Grid Strain

EV chargers, especially DC fast chargers, can draw power in sudden, intense bursts. If transformers feeding these stations aren’t properly rated or coordinated with site loads, it can lead to voltage fluctuations, localized transformer stress, and reduced power quality.

Excessive Energy Losses

Every transformer incurs some level of energy loss, but inefficient designs result in greater core and load losses, especially when handling harmonic-rich or continuous loads from EV charging. These losses translate to higher operational costs, heat generation, and reduced overall system efficiency.

Overheating and Reduced Equipment Lifespan

Transformers not built for variable, high-frequency loads can experience thermal stress. Excessive heat degrades insulation and core materials over time, shortening the life of not just the transformer itself, but also connected components like conductors, fuses, and protective devices.

Unexpected Costs for Replacements or Upgrades

Using an underspecified transformer can lead to premature failure, frequent maintenance, or the need to upsize equipment as demand increases. This creates costly disruptions and longer project timelines; issues that can often be avoided by choosing the right transformer from the start.

The Hidden Hero of EV Charging: Why Transformers Matter

The reality is: EV charging isn't like powering a lightbulb or running an air conditioner. High-frequency switching, harmonic distortion, and fluctuating load profiles are just part of the challenge.

EV charging, especially Level 3 fast chargers, can draw immense power in short bursts, but they don’t do so consistently. Variable loads are common, with stations cycling between idle, trickle, and peak demand. That creates unique thermal demands on the transformer, requiring solutions that go beyond general-purpose designs.

Modern EV charging transformers address these challenges with:

- Harmonic mitigation using K-rated cores to manage non-linear loads without overheating.

- Thermal management designed to handle frequent charging cycles, variable loads, and continuous high demand, ensuring long-term reliability.

- Outdoor durability with Type 3R and 3RE plus rated enclosures for extreme environments.

- Energy efficiency, with optimized core designs and low temperature rise options to reduce energy losses and improve performance.

The right transformer reduces energy waste, protects the charger, and ensures long-term reliability.

Designing for Demand: What Makes a Transformer EV-Ready?

So what should developers, engineers, and utilities look for in a transformer that’s truly EV-Ready?

Here are a few key attributes:

- K-Rated Core Options

K-rated transformers are designed to handle harmonic currents without overheating. EV chargers, especially those using power electronics, create harmonics that can degrade traditional transformers over time. - Low Temperature Rise

A transformer with a 115°C or 80°C rise option can run cooler and last longer in demanding, high-load environments, which is especially important for continuous use scenarios. - 3R or 3RE plus enclosures

More often than not EV sites are outdoors. A suitable enclosure ensures the transformer can withstand rain, snow, and dirt without sacrificing safety or performance. - Time-Saving Installation Features

Ease of installation matters especially when deploying multiple charging stations across sites. Transformers designed with practical features like outward-facing mounting feet and removable drip shields help simplify setup, reducing labor time. - Custom Appearance Options

Especially for urban or public-facing sites, transformers with custom color options can blend seamlessly into the environment, helping meet zoning and aesthetic requirements.

Charging Ahead Requires a Strong Foundation

As EV adoption accelerates, scalable, reliable infrastructure is non-negotiable. Transformers are the foundation of every successful charging installation, but only if they’re built to meet the unique demands of EV charging.

If we’re serious about building a greener, electrified future, it’s time to give transformers the attention they deserve.

Because the right transformer doesn’t just support the load, it powers the future.

Looking for a transformer for your EV Charging installation?

Check out our line of HPS EV Charging Distribution Transformers. Made to meet the rigours of any EV charging installation.

More from the HPS Blog

Cast-Resin Transformers for High-Profile Manhattan Financial Firm - Case Study

HPS delivered custom cast-resin transformers to a Manhattan financial firm, overcoming major logistical challenges to support critical infrastructure.