Case Study: Improving Transformer Reliability for Underground Mining Power Systems

Segment and Application

The customer is a regional provider of engineered electrical solutions for mining and industrial applications in Mexico. They design and integrate customized power distribution equipment and electrical systems for harsh environments, including underground mining operations.

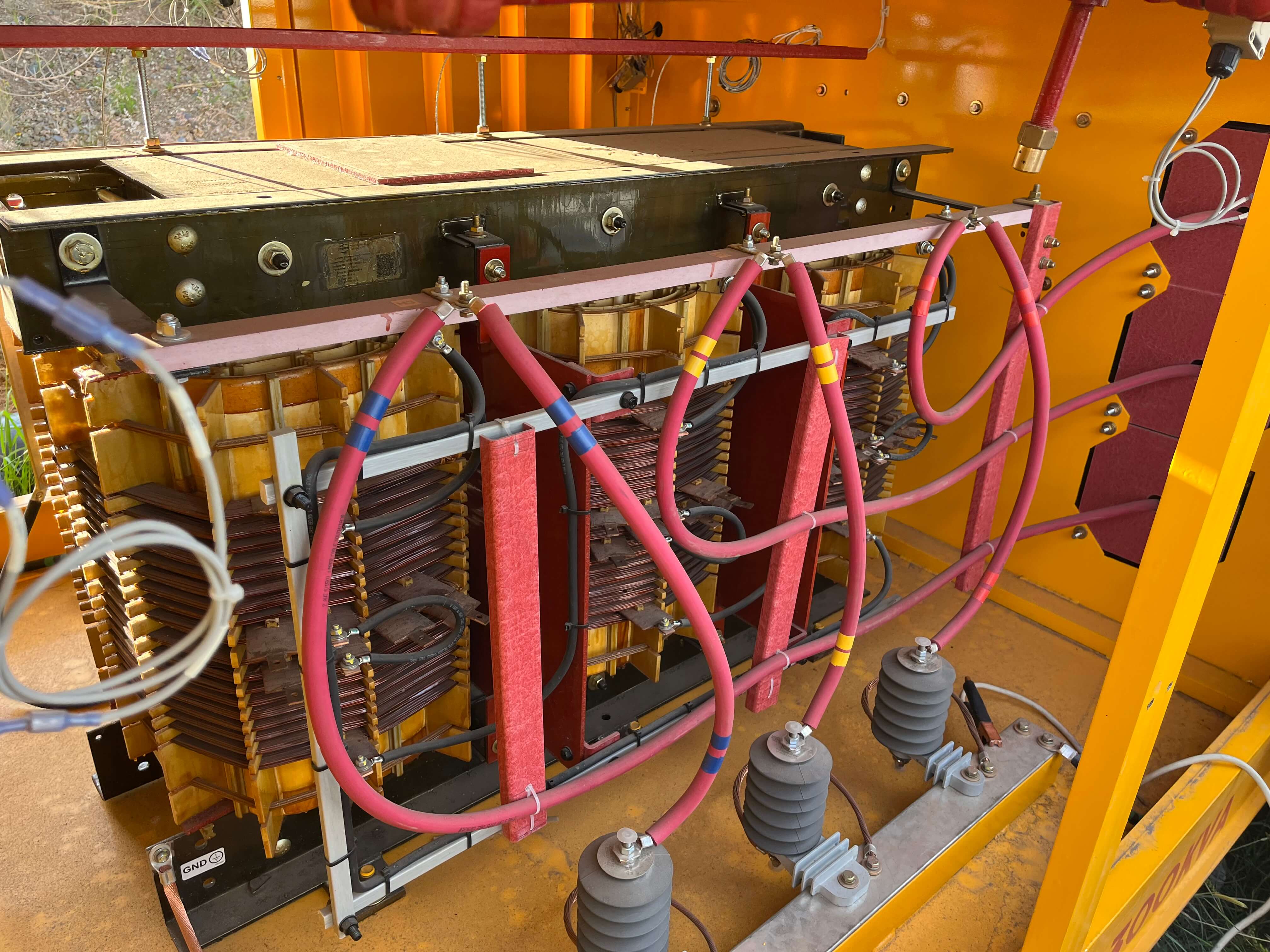

As part of this work, they required compact power solutions for underground mining skids deployed across multiple sites in Mexico for various mining companies. These skids support a range of mining operations and were built in several configurations, ranging from 500 kVA to 1500 kVA, with voltages including 4,160–480Y and 13,800/13,200–480Y. The equipment operates in demanding underground environments where dust, vibration, and limited access are part of daily operation.

The Design Challenge

The project involved delivering transformers designed to support underground mining skids across a wide range of ratings and voltages. While the original design met electrical requirements, early field experience showed that environmental conditions in certain underground applications were more severe than anticipated.

Key challenges identified:

- Harsh underground conditions with high levels of conductive dust

- Compact skid designs limiting airflow and increasing exposure to contaminants

- Medium-voltage operation increasing sensitivity to insulation degradation

- Environmental stresses accelerating insulation breakdown in confined spaces

- Need for a winding design better suited for long-term underground service

HPS worked alongside the customer and field service teams to evaluate the operating conditions directly and identify the most appropriate path forward. Site visits and testing helped confirm that a different winding approach would provide improved long-term reliability in these environments.

The HPS Solution

Based on field observations and collaborative review, HPS transitioned the affected units to a barrel-wound coil design. This construction offers improved resistance to conductive dust accumulation and better alignment with the realities of underground mining conditions.

HPS coordinated the redesign and delivery of the updated transformers, working closely with engineering, field service, and customer teams to ensure consistent performance across all sites.

Results

- Improved insulation performance in dusty environments

- Increased reliability for medium-voltage underground skids

- Stronger alignment between transformer design and site conditions

- Renewed confidence from the customer and end users

Customer outcome:

The project resulted in a more robust transformer solution now operating across multiple mining sites in Mexico for various mining companies. By adapting the design based on real-world conditions, HPS delivered a solution well suited for harsh underground environments and strengthened long-term customer relationships.

More from the HPS Blog

Power Quality Stabilization for Renewable Natural Gas Facilities - Case Study

During a recent project, a customer approached HPS with concerns about electrical instability at one of their landfill RNG facilities.