Application Decision Making: Active Harmonic Filters vs. 18-Pulse Drives

About Harmonics

There have been various solutions developed for mitigating harmonic distortion over the past couple of decades. Harmonics became an increasingly important issue as more facilities have begun to use variable frequency drives (VFDs) creating an immense burden on our utility grid. Engineers will attempt to specify the harmonic limits for bus loads, which include switchgear and motor control centers (MCC), in order to help to mitigate this problem.

IEEE-519-2014 provides a guideline for Total Harmonic Distortion (THD) limits that are being increasingly enforced by utility companies in North America, in an attempt to maintain power quality for their customers. IEEE-519 requires that each facility at the Point of Common Coupling (PCC) meet certain THD levels. These levels are based on several considerations within the facility and the utility that is providing the power. The PCC is clearly defined as the point where the utility power enters the facility, not at each drive input.

These recommendations necessitate facilities to utilize 18-pulse drives or use an additional filter with 6-pulse drives, which can significantly increase initial equipment installation costs.

The following article will provide a comparison of 18-pulse drives with the use of 6-pulse drives combined with an active harmonic filter. These are both proven methods of decreasing harmonic distortion to below IEEE-519 levels. However before we can compare these two systems we need to take time to give an overview how both of these different solutions work and how they address harmonic distortion issues.

18-Pulse Drives

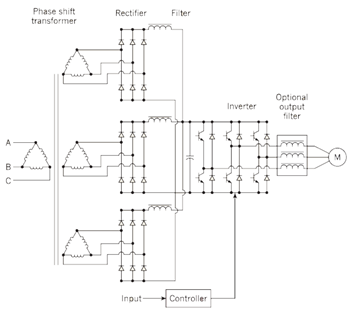

18-pulse drives work similarly to 6-pulse or 12-pulse drives, except they incorporate three separate input semiconductor bridges (instead of one or two). Three separate 3 phase 6-pulse converters have a phase shift of 20°, which feed into an inverter. This phase-shift is achieved by utlizing a specially wound input transformer. This effectively cancels most harmonics below the 17th order by the summation and cancellation of the harmonic currents of equal amplitude but opposite phase. Designed input impedance mitigates higher order harmonics as well.

18-pulse drives work similarly to 6-pulse or 12-pulse drives, except they incorporate three separate input semiconductor bridges (instead of one or two). Three separate 3 phase 6-pulse converters have a phase shift of 20°, which feed into an inverter. This phase-shift is achieved by utlizing a specially wound input transformer. This effectively cancels most harmonics below the 17th order by the summation and cancellation of the harmonic currents of equal amplitude but opposite phase. Designed input impedance mitigates higher order harmonics as well.

With a balanced voltage and at full load an 18-pulse drive is a solution that can meet IEEE-519-1992 requirements. It is successfully able to reduce harmonics significantly, to around 5% if loaded properly. If voltage unbalances are present, it will not mitigate harmonics as specified. This is one of the more expensive solutions for correcting harmonic distortion because it is generally custom built and is made with costly, large magnetics.

Active Harmonic Filters

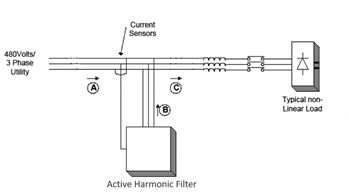

Active harmonic filters use intelligent electronics and IGBTs to inject corrective current into the power system to correct for the harmonics generated by non-linear loads. Systems are installed in parallel to the utility line and sensors are used to monitor the line and determine the amount of corrective current that must be injected to ensure the utility provides a sinusoidal waveform.

Active harmonic filters can be used to compensate for both harmonic distortion and power factor, and one unit can be used to compensate for multiple non-linear loads. It is able to operate at its maximum current rating and not be overloaded, even if new loads are installed. Multiple active harmonic filters can be installed in parallel to supply corrective current for larger applications. They are able to function properly if voltage imbalances exist. Active harmonic filters can be a more costly solution for a single drive application, but as one filter is used to correct for multiple loads, they become a more cost effective solution.

Active harmonic filters can be used to compensate for both harmonic distortion and power factor, and one unit can be used to compensate for multiple non-linear loads. It is able to operate at its maximum current rating and not be overloaded, even if new loads are installed. Multiple active harmonic filters can be installed in parallel to supply corrective current for larger applications. They are able to function properly if voltage imbalances exist. Active harmonic filters can be a more costly solution for a single drive application, but as one filter is used to correct for multiple loads, they become a more cost effective solution.

Comprehensive Comparison

Advantages of 18-Pulse Drives

- Some cost savings can be realized in comparison to active harmonic filters if there is a single, large drive

- Provides increased input protection for a VFD and its semiconductors from line transients

- Can be IEEE-519 compliant if voltage is balanced and operating at full load

- Smaller transformer than isolation transformer used in 12-pulse converter

- 18-pulse drives are extremely robust systems

Advantages of Active Harmonic Filters

- While an 18 pulse drive generally meets the harmonic limits specified in the IEEE-519, an active harmonic filter, if sized correctly, guarantees that the standard is met, making THD less than 5%

- Parallel installation of active harmonic filters provides for easy installation with no major system rework, while the installation of an 18-pulse drive requires complete replacement of each existing drive

- If maintenance is required on an 18-pulse drive then downtime is needed. Since an active harmonic filter is installed in parallel it can be maintained while the drive(s) are running.

- Active harmonic filters provide harmonic mitigation through the 51st harmonic, while 18-pulse drives do not address as much of the harmonic spectrum

- If line voltage unbalances are present of more than 1%, then an 18-pulse drive will not correct as well as an active harmonic filter; if a 1% voltage unbalance is present an 18 Pulse drive may not meet the IEEE-519 current distortion requirements.

- Active harmonic filters provide reactive currents that improve system power factor, unlike 18-pulse drives

- If using an 18-pulse drive, a front end is required for each drive product, while one active harmonic filter can correct for multiple 6-pulse drive systems

- 18-pulse drive footprints’ may be a concern, especially for retrofit projects; active harmonic filters can be integrated with MCC’s switch gear, which dramatically reduce space and cost when compared to an 18-pulse drive

- Series type 18-pulse drive arrangements may have losses and efficiency reduction, which increases harmonic levels, electricity costs, and cooling costs, when compared to an active harmonic filter

- Use of multiple 18-pulse drives and no active filters (equipment, installation, and operating costs) typically have a higher cost point when compared to multiple 6-pulse drives with an active harmonic filter

- Maintenance, repair, and replacement of 6-pulse drives are significantly faster and less complicated than that of 18-pulse drives

Conclusion

Both systems can be effective at mitigating harmonic distortion, and it often depends on each individual facility to determine which approach to use. In certain situations where a single large VFD is present an 18-pulse drive may be the more cost effective option, however active harmonic filters can be more cost effective if there are multiple VFDs (non-linear loads) in the facility. The active harmonic filter is the only solution to guarantee that IEEE519 recommendations are met, even when voltage unbalance exists or if a load is not expected to run at its maximum (which are both common). In addition, as the cost of copper and magnetics continue to rise, the active harmonic filter will become more cost effective.

References

- Commercial Systems.” Globalcon, 2003, Boston, MA.

- IEEE Standard 519-1992-IEEE Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems

- Todd Shudarek, “Harmonic Mitigation in Variable Frequency Drives: 6-Pulse Drives with Harmonic Filter vs. 18-Pulse Drive.” MTE, 2012, Menomonee Falls, WI.

- Singh, B.; Al-Haddad, K. and Chandra, A. (1999) A review of active filters for power quality improvement”, IEEE Trans. Industrial Electronics, vol. 46, no. 5, pp. 960-971.

- “Comparing the Danfoss Harmonic Filter with traditional multi-pulse solutions.” Danfoss, 2007

- Nick Guskov, “Straight Talk about PWM AC Drive Harmonic Problems and Solutions.” Rockwell Automation, Mequon, WI.

- Tony Hoevenaars, “18-Pulse VFD vs Lineator/6-PulseVFD.” Mirius Internation, Inc., 2003, ON, Canada